-

Customized Steel Stainless copper brass aluminium Electronics & auto part

CNC turning machining Parts OEM Customized Steel Stainless copper brass aluminium Electronics & auto part

Advantages of CNC lathes

1. Precision and Accuracy

2. Versatility

3. Efficiency and Productivity

4. Consistency and Repeatability

5. Complex Geometries

6. Cost-effectiveness

7. Customization and Prototyping

-

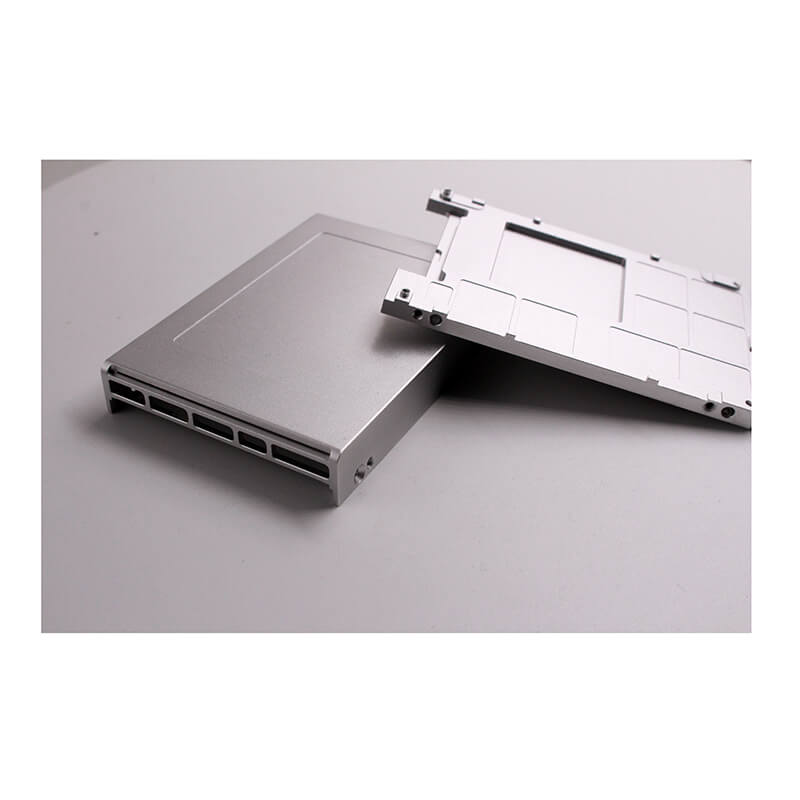

Stainless Steel Parts Cnc Machined Aluminum Cnc Machining Parts

A Machining Process That Rotates a Workpiece While a Cutting Tool Removes Material from the Surface, Suitable for Cylindrical or Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods. Advantages: High Precision, Repeatability,And Efficiency in Mass Production.

-

oem custom center parts machining aluminium cnc

Our lathe parts are metal parts that have been machined with high precision, manufactured by using advanced lathe technology. With high-quality materials and precise machining technology, we provide high-quality lathe parts to meet the various needs of customers.

-

brass cnc turning machining anodized aluminum mechanical part

CNC turning utilizes advanced machinery guided by computer programming, ensuring high levels of accuracy and repeatability. This precision is essential for industries that require tight tolerances and intricate designs.CNC turning offers fast and efficient production capabilities. The automation and multitasking capabilities of CNC machines allow for rapid material removal and reduced cycle times, resulting in increased productivity and shorter lead times.

-

aluminum milling turning service CNC machining parts

We provide CNC machining services and can customize the production of aluminum parts, stainless steel parts, copper parts, shafts, etc. Using computer-controlled machines to strictly follow design specifications, achieving consistent dimensions, strict tolerances, and complex geometric shapes. This precision ensures the optimal fit, functionality, and performance of the final product.

-

5 Axis Precision Steel Aluminium CNC Turning Machining Part

Dongguan Custom CNC Machining Milling Machinery Fabrication Services 5 Axis Precision Steel Aluminium CNC Turning Machining Part

-

Aluminum Stainless Steel CNC Lathe Turning Machining Parts

CNC lathe turning machining parts refer to the components or parts that are manufactured using CNC lathe machines. These machines use computer numerical control (CNC) technology to precisely shape and cut materials.

We can produce Shafts, Bushings, Pins, Fasteners, Spacers, etc. through CNC lathes

-

cnc precision aluminum part turning machining custom parts

Professional manufacturing cnc precision aluminum part turning machining custom parts for sale

OEM/ODM accept

Professional in both Non-Standard parts and standard parts

Fast lead time

Professional team

More than 30years experience in metal part machining

24 hours online service

Whether you’re putting together electronic devices, building industrial machines, or piecing together lightweight structures, aluminium CNC parts are total must-haves. With these carefully crafted components, you can get tight, reliable connections without any hassle—plus, they cut down on overall weight and make your projects last longer. Don’t sell ’em short: they’re not just great at fighting corrosion , but they also stay structurally stable no matter the temperature. And when standard parts can’t fit into those tight or tricky designs? These guys slide right in perfectly.

Common Types of Aluminium CNC Parts

Aluminium CNC parts are made to handle real-world assembly jobs—some are awesome for lightweight fastening, others can take repeated pressure, and a few are specifically designed for those tiny spaces in electronics. These three are the ones you’ll grab most often when you’re working:

Aluminium Screws:These screws have a clean, precision-machined look, and they come with standard threads or ones we can custom-make. Most have cross-recessed, slotted, or hex socket heads. The best part? They’re super light, but strong enough for jobs that don’t need heavy torque—you’ll see ’em in laptop cases, smartphone frames, or drone parts, where you need to cut weight but still keep things held tight.

Aluminium Standoff:Aluminium standoffs have a cylindrical body, with threaded holes on one or both ends and a raised flat shoulder in the middle. Just line up its threaded end with a pre-tapped hole or fasten it with a matching screw—it’ll instantly create a steady. No fancy tools or fussy spacing tweaks needed, super easy to use. Made with CNC machining, the surface is smooth with no burrs—looks nice and won’t scratch the parts it’s paired with.

Aluminium Heat Sinks: We craft these heat-dissipating components by first extruding aluminium to form base structures and fins, then refine them with precision machining to match your thermal needs—think CPU coolers, LED light heat sinks, or power supply radiators. They’re engineered to meet strict dimension standards, so they attach to devices seamlessly without thermal gaps.

Aluminium CNC Part:Aluminium CNC parts feature precise, custom-shaped bodies tailored to design needs, with standardized holes, grooves or threads for seamless assembly.Just align it with matching components or fasten via its pre-machined interfaces—it’ll form a stable, tight connection right away. No manual trimming or adjustment required, operation is straightforward.Crafted through high-precision CNC machining, every dimension meets strict tolerances—ensures consistent performance and won’t cause fitting issues with paired parts.

Application Scenarios of Aluminium CNC Parts

Picking the right aluminium CNC part isn’t just about making it fit—it also keeps your equipment from getting damaged and makes sure it works well for a long time. Here are the most common spots where you’ll use these parts:

1. Vehicle-Mounted Electronics

Core Parts: Vehicle-mounted aluminum fixing screws, small aluminum fasteners, aluminum heat sinks

Uses:

Secure in-vehicle navigation/central control internal parts (e.g., motherboards) without scratching circuits; stay tight on bumpy roads.

Fasten wireless charging module housings to avoid cracking; heat sinks prevent overheating and ensure charging safety.

Fix HUD brackets (lightweight) and cool built-in chips to avoid blurry displays.

2. Automotive & Transportation

Core Parts: Aluminum wheel nuts, suspension bushings, brake caliper brackets

Uses:

Wheel nuts: Maintain torque on rough roads, reduce unsprung weight for smoother rides.

Suspension bushings: Resist wear/high temps (-30℃~150℃), reduce noise.

Brake brackets: Rust-proof, lightweight (40% lighter than steel), boost emergency braking response.

3. Vehicle-Mounted Accessories & Auto Production

Core Parts: Aluminum connector pins (for accessories), support clamps (for production lines), heat sinks (for auxiliary devices)

Uses:

Connector pins: Secure car fridges/storage racks; resist vibration/corrosion.

Production clamps: Fix car bodies/doors for precise assembly; resist oil/coolant.

Heat sinks: Cool auxiliary devices (e.g., rear-seat screens) to avoid malfunctions; lightweight.

How to Customize Exclusive Aluminium CNC Parts

At Yuhuang, customizing aluminium CNC parts is simple—no guessing, just parts that fit your project like they were made for it (because they are). All you need to do is tell us a few key things:

Material Grade:What does your project need? 6061 aluminium is great for most jobs—it balances strength and corrosion resistance, so it works for screws or brackets. 5052 aluminium is more flexible—perfect for stamped parts that need bending, like washers or small housings. 7075 aluminium is super strong—good for high-torque jobs, like automotive structural parts. Just let us know how strong you need it and how much weight you want to cut.

Type & Function:What kind of part do you need? We can customize aluminium screws with different thread lengths (for deep or shallow holes), different head types , or even anti-slip coatings. For aluminium rivet nuts, we can do custom thread sizes (to match non-standard bolts) or flange diameters (for more contact on thin materials). And aluminium stamped parts? We can shape ’em into whatever you need—like custom brackets for medical devices or sensor housings for industrial gear.

Dimensions:Got specific sizes in mind? For aluminium screws, tell us the thread diameter (like M3 or 1/4 inch) and length (so it fits the depth of your assembly). For rivet nuts, let us know the hole size it needs to fit (like 5mm pre-drilled holes) and thread pitch (coarse or fine). For stamped parts, give us the exact length, width, and thickness—down to 0.1mm. We’ll make sure every piece matches your blueprint perfectly.

Surface Treatment:How do you want it to look and work? Anodizing (we can do clear, black, or custom colors) adds a protective layer, makes it more corrosion-resistant, and gives it a clean finish—great for parts people will see, like furniture or gadgets. Sandblasting gives it a matte, non-slip surface—good for screws or brackets that need grip. We can also add lubricant coatings (for screws you need to take off often) or anti-static treatments (for electronic parts).

Special Needs:Got any extra requests? Like an aluminium screw with a hex head on one end and Phillips on the other? Want your brand logo engraved on a stamped bracket? Need a rivet nut that can handle high temperatures (for engine parts)? Just say the word—we can make it happen.

Share these details with us, and first we’ll check if it’s doable. If you need advice—like which aluminium grade to pick—our team is happy to help. Then we’ll send you parts that fit your project like a glove.

FAQ

Q: How do I pick the right aluminium CNC part for my project?

A: For light electronics (laptops/phones), use 6061 screws—small, rust-resistant. Thin metal sheets (car trim/furniture)? Go with rivet nuts (no welding). Bulk custom parts (grilles/brackets)? Stamped parts are cheap in large orders. Match to weight, strength, assembly.

Q: What if an aluminium screw strips or a rivet nut won’t lock?

A: Stop using it. Stripped screw? Use a perfect-fit driver (e.g., 2mm hex for M3). Rivet nut won’t lock? Check the hole—too big = no grip, too small = cracks. Replace part, adjust hole if needed.

Q: Do aluminium CNC parts need maintenance?

A: Yeah. Wipe dirt/oil/moisture with a dry cloth after use. Anodized parts? Use mild soap (no harsh cleaners). Outdoor parts? Check yearly—aluminium doesn’t rust, but weather harms threads.

Q: Can I use aluminium rivet nuts on plastic/wood?

A: Depends. Thick plastic (ABS/PVC) or hardwood (oak)? Yes—smaller nut, lower pressure. Thin plastic/soft wood? No—they’ll break. Use plastic rivets/wood screws instead.

Q: Is 6061 better than 5052 for stamped parts?

A: Depends. Need bending (curved brackets)? 5052 is flexible (no cracks). Need strength (heavy washers)? 6061 is sturdier. Pick for flexibility or strength.

Bolts

Bolts Nuts

Nuts Wrenches

Wrenches Spring

Spring