Common Types of Pins

Pins aren’t all the same—you wouldn’t use a wrench for a screwdriver, right? Some lock tight, some adjust easy, some just keep parts straight. Here are the ones you’ll actually run into, with the real scoop on carbon and stainless steel versions:

Carbon Steel Pin:This is the “workhorse” you’ll see everywhere—usually made from low or medium-carbon steel (1045’s the most common, if you’re curious). The big win? It’s super strong—I’ve used these on pulley shafts that hold heavy belts, and they never bend. The catch? Dampness is its enemy. I once had a carbon steel pin on a outdoor cart rust solid in a month—so either plate it with zinc or use it inside, like on machinery hinges.

Stainless Steel Pin:304 stainless is the go-to here, and for good reason. Rain, road salt, even mild chemicals? It doesn’t care. You don’t need extra plating, and it’s strong enough for most jobs—plus, it’s not magnetic. That’s a lifesaver for electronic boxes or medical gear—last year, a customer used these to mount circuit boards, and no more interference with the electronics. No more “why’s the machine glitching?” because of a magnetic pin.

Application Scenarios of Pins

Picking the right pin isn’t rocket science, but it matters—use the wrong one, and you’ll be fixing it again next week. Here’s where each type works best:

1. Industrial Machinery and Manufacturing

● Common types: Carbon Steel Pin, Cotter Pin

● Typical uses: Conveyor belt rollers? Carbon steel handles the weight of boxes or parts—no bending, even when it’s running all day. Gearbox shafts? Cotter pins stop nuts from shaking loose (I’ve seen what happens when they do—big mess). Hydraulic cylinder rods? Zinc-plated carbon steel resists rust from the oil—no more stuck rods.

2. Automotive and Transportation

● Common types: Stainless Steel Pin, Carbon Steel Cotter Pin

● Typical uses: Suspension parts? Stainless steel stands up to road salt in winter—no rust eating through the pins. Brake caliper bolts? Add a cotter pin—extra safety so the bolt doesn’t come loose (brakes are non-negotiable, right?). Engine timing gears? Precision-cut carbon steel keeps torque steady—no more off-timing issues.

3. Electronic and Medical Equipment

● Common types: Stainless Steel Pin

● Typical uses: Server racks with circuit boards? Non-magnetic stainless steel won’t mess with the electronics—no more random shutdowns. Medical device casings? Smooth stainless doesn’t scratch the sensitive parts inside—hospitals love that. Diagnostic gear motors? Rust-resistant means it meets hygiene standards—no more cleaning rust off pins near medical tools.

4. Construction and Heavy Equipment

● Common types: Carbon Steel Pin, Hot-Dip Galvanized Stainless Steel Pin

● Typical uses: Excavator bucket links? High-strength carbon steel handles digging through dirt and rocks—these things take a beating. Scaffolding joints? Hot-dip galvanized stainless steel won’t rust outside, even in rain. Crane boom sections? Thick carbon steel passes along weight safely—no more worrying about the boom slipping.

How to Customize Exclusive Pins

At Yuhuang, we don’t do confusing jargon—just tell us what you need, and we’ll make it. I’ve helped customers customize pins for everything from small hobby machines to big construction gear, and it’s always the same 5 simple things we need:

1.Material: 1045 carbon steel if you need strength (like for heavy machinery), 304 stainless for rust resistance (outdoor or damp spots), or 316 stainless if you’re dealing with tough chemicals (like in factories).

2.Type: Carbon steel for heavy loads, stainless for durability, or cotter pin for locking—just pick what fits your job.

3.Dimensions: Tell us the size—inner diameter if it’s hollow (needs to fit over a shaft), outer diameter (has to match the hole in your part—no guesswork here), length (depends on how thick the parts you’re connecting are), and any tapers or grooves (to keep it from slipping out).

4.Surface Treatment: Zinc plating for indoor rust protection (great for carbon steel), black oxide for scratch resistance (looks nicer too), or hot-dip galvanizing for outdoor use (stainless or carbon—lasts years).

5.Special Needs: Anything extra? Non-magnetic for electronics? Heat resistance for engine parts (we had a customer need this for exhaust systems—worked perfectly)? Even custom engravings (to mark your brand or part number—handy for inventory)?

6.Share these and we will reply to you within 24 hours to see if it's feasible. I even offer some suggestions. For instance, previously, a customer wanted carbon steel for outdoor use. I suggested using hot-dip galvanizing to avoid rusting problems. We ensure that the final needle fits, as if they were just for your setup - not "close enough" here.

FAQ

Q: How do I choose between carbon steel and stainless steel pins?

A: Easy—if it’s inside (machinery hinges, indoor carts) and you want strength on a budget, go carbon steel. If it’s outside, damp, or near electronics/medical gear (car parts, server racks), stainless steel is the way. I’ve had customers pick carbon for indoor use and save 20%—works every time.

Q: What if a pin keeps slipping out of the assembly?

A: Swap for a cotter pin—bend the ends, and it won’t move. Or add a retaining ring. If there’s a lot of vibration (like in a motor), use a grooved pin—it grips the hole better. I once had a customer use thread-locking glue on a pin in a shaky machine—no more slipping.

Q: Should I replace pins when I replace bolts or nuts?

A: Yeah, definitely. Pins wear out—carbon steel rusts, stainless steel gets scratched—and that makes ’em less accurate. Last year, a guy reused old carbon steel pins on his tractor’s suspension, and they snapped a week later. Not worth the risk—replace ’em with the bolts.

Q: Can stainless steel pins handle high temperatures?

A: 304 stainless works up to about 800°F—fine for most jobs. If you need hotter (like engine exhaust, which gets to 1,800°F), use 310 stainless—it handles up to 2,000°F. Just check with us first—we’ll make sure it’s right for your temp.

Q: Do I have to replace rusted carbon steel pins?

A: If it’s just a little rust (no bending or pitting), clean it with a wire brush and use it for non-important stuff—like a furniture hinge. But if it’s rusted bad, bent, or in something safe-critical (brakes, construction gear)? Replace it. I’ve seen rusted pins snap on scaffolding—never worth cutting corners.

Bolts

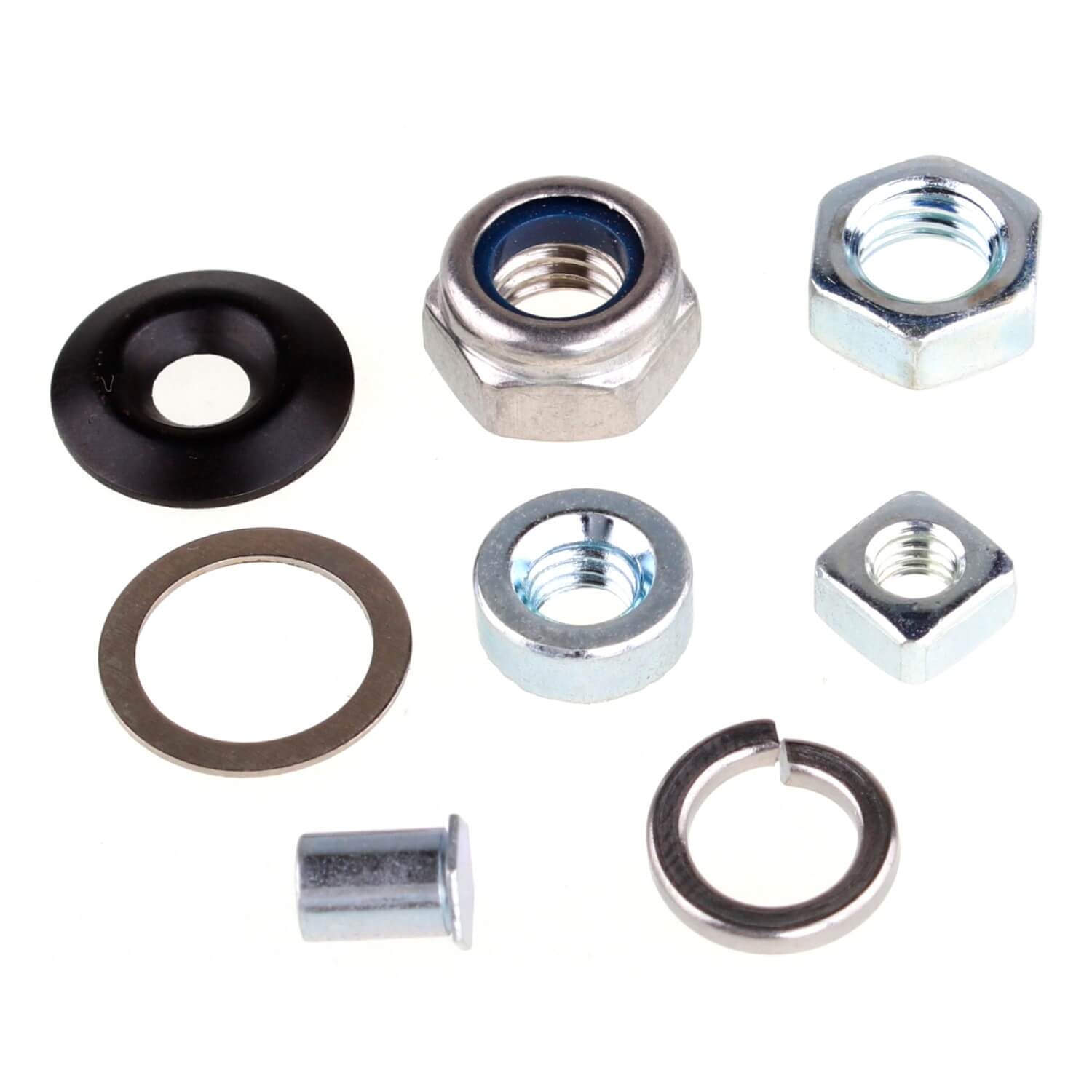

Bolts Nuts

Nuts Wrenches

Wrenches Spring

Spring