Two Common Types of Springs

Springs are designed based on practical needs. Some excel at withstanding pressure, while others are good at stretching and rebounding. These two types are most widely used in mechanical and daily scenarios:

Tension Springs:They’re pretty simple in design. Pull ’em, and their coils stretch out; let go of the force, and they shrink right back to how they were. They’re easy to put in place, don’t cost much, and work great for times when you need steady tension. You’ll see ’em all over daily life.

Compression Springs:Their coils are wound quite densely. When pressed hard, they shorten; once the pressure is released, they can bounce back to their original length. Unlike tension springs, these are mainly used to absorb impact force and store pressure. Thanks to their dense coil structure, pressure gets evenly spread across the whole spring.

Where Springs Actually Get Used

Picking the right spring isn’t just about matching force and stretch—it’s what keeps the whole machine safe, running smooth, and from breaking down too soon. Here’s where tension springs (the ones that pull) and compression springs (the ones that push back) really do their job in real life:

1. Factory Machines

Springs you’ll see here: Heavy-duty tension springs, tough compression springs

These springs are the quiet helpers on factory floors. Take conveyor belts—those big ones moving parts or boxes? Heavy-duty tension springs keep the belt tight so it doesn’t slip, so stuff gets where it needs to go without messing up. Then there’s stamping or forging machines—they hit hard when shaping metal. The tough compression springs soak up that shock, so the machine parts don’t wear out fast, and the whole thing lasts longer. Even chemical plants use them: their valve systems have tension springs that yank valves shut if the power goes out. That way, no dangerous chemicals leak out—total safety backup.

2. Cars & Vehicles

Springs you’ll see here: Shock-absorbing compression springs, precise tension springs

Cars wouldn’t ride right (or be safe) without these. The suspension under your car? It has shock-absorbing compression springs that work with the shocks to smooth out potholes and bumpy roads. No more bouncing all over the place—you stay steady, and the ride’s way comfier. After you hit the brakes, precise tension springs pull the brake pads back from the discs. If they didn’t, the pads would rub nonstop, wearing out fast and costing you more to replace. Even car seats use tiny compression springs: they hold up the parts that let you adjust height or angle, so you never get stuck mid-tweak.

3. Everyday Stuff & Home Appliances

Springs you’ll see here: Light tension springs, tiny compression springs

We use these springs all the time and barely notice. Garage doors, for example—light tension springs balance the door’s weight. That’s why you can lift a heavy garage door by hand (or why the motor doesn’t have to work overtime). Mattresses with coils? Those tiny compression springs spread your weight out so you don’t sink too far, and your back gets support while you sleep. Even toasters use them: when your bread’s done, a tension spring pops the tray up. And when you press the tray down to start toasting? A little compression spring holds it in place until the bread’s ready.

4. Medical Tools & Precision Gear

Springs you’ll see here: Super-precise tension springs, rust-proof compression springs

Medical stuff needs springs that are both exact and tough to clean—and these fit. Syringes, for instance—super-precise compression springs control how fast medicine pushes out, so the doctor or nurse can give the exact dose you need. Wheelchairs have tension springs in their brakes: when you lock the brakes, those springs keep them tight, so the chair doesn’t roll away by accident. Dental drills? They use rust-proof compression springs to keep spinning at a steady speed. And since they don’t rust, they hold up to all the chemical cleanings dental tools need to stay germ-free.

How to Customize Exclusive Springs

At Yuhuang, we’ve kept spring customization super simple—no confusing jargon, just the right springs that fit your equipment like a glove. All you gotta do is tell us a few key things, and we’ll handle the rest:

1.Material: Pick from stuff like carbon steel (great for regular, everyday use—tough enough to last), stainless steel 316 (total pro at fighting rust, perfect if it’s gonna be in humid spots or around chemicals), or titanium alloy (lightweight but surprisingly strong, ideal for gear that needs top performance).

2.Type: Like, compression springs (they push back when you press ‘em—you’ll find ‘em in car suspensions or door hinges), extension springs (stretch out when you pull ‘em, common in garage doors or trampolines), or torsion springs (twist when you put force on ‘em, usually in clothespins or mousetraps).

3.Dimensions: Wire diameter (thicker wire means a stronger spring, so just go with what force you need), outer diameter (has to fit the space where you’ll put the spring), free length (how long the spring is when it’s not being pushed or pulled), and total coils (this affects how much the spring can stretch or compress).

4.Surface treatment: Options like electrophoresis (adds a smooth protective layer—works well for indoor machines), powder coating (tough and scratch-proof, great for springs used in outdoor tools), or nickel plating (boosts rust resistance and gives a nice, clean look for precision equipment).

5.Special needs: Any weird or specific requests—like springs that can handle super hot or cold temps (for industrial ovens or freezers), custom colors to match your brand, or odd shapes that fit unique equipment designs.

Just shoot us these details, and our team will quickly let you know if it’s doable. If you’re not sure about anything, we’ll throw in helpful tips too—and get you springs made exactly how you want ‘em.

FAQ

Q: How to pick a spring with the right force?

A: First find your equipment’s required working force (e.g., a 50kg chair needs ~500N, via F=mg) and choose a spring with a close rated force. For shock absorption (like car suspensions), pick one with dynamic load 1.2-1.5x max impact force. Can’t calculate? Share your load scenario for help.

Q: Why do springs lose elasticity over time?

A: Mostly “fatigue failure” (e.g., using a 100,000-cycle spring for 200,000 cycles damages its structure). Wrong materials (e.g., low-carbon steel for heavy loads) or unfit high-temp use (no heat-resistant material) also cause this. Replace with a spring matching cycle, load, and temp needs.

Q: Can springs work in corrosive environments?

A: Sure they can—just need to get the material and surface treatment right. For damp workshops, 304 or 316 stainless steel is fine. If it’s super harsh, like chemical tanks, go with titanium alloy. Then add something like zinc-nickel plating (way better than regular zinc) or PTFE coating—those stand up to strong acids and alkalis. Also, wipe them down now and then with neutral detergent to keep them in shape. And don’t use regular carbon steel—those rust in no time.

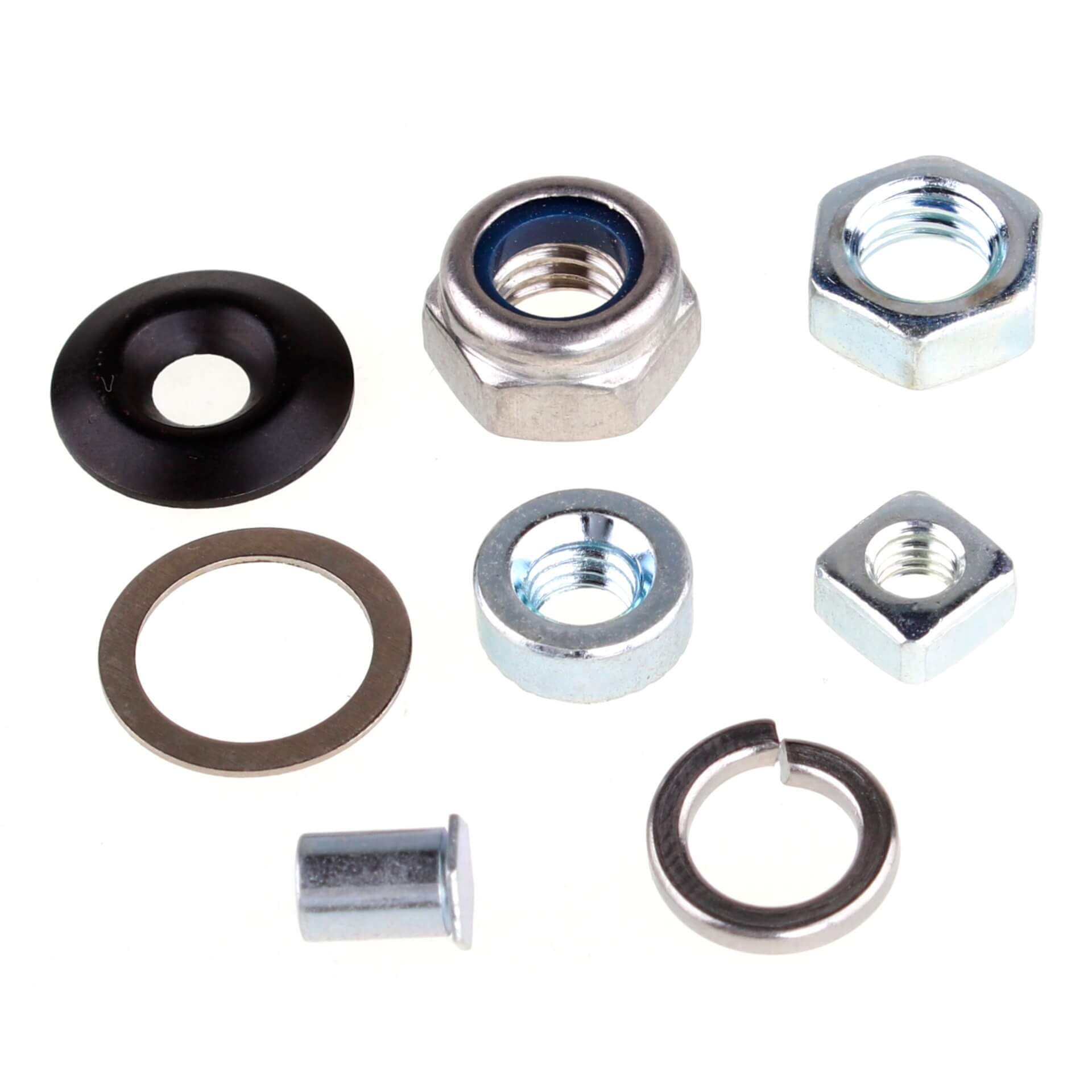

Bolts

Bolts Nuts

Nuts Washers

Washers Screw

Screw