-

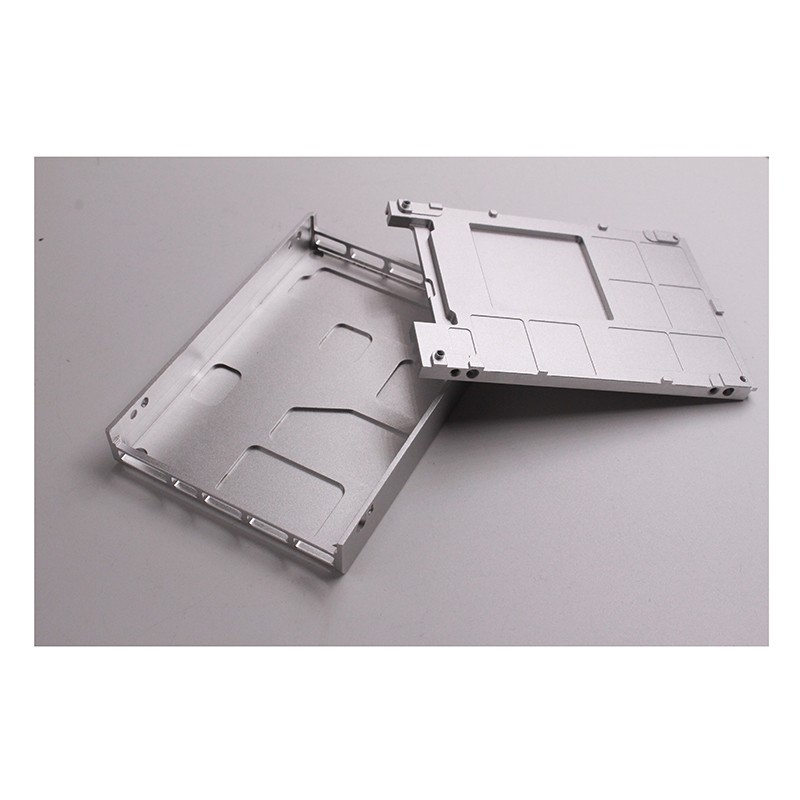

Custom Precision CNC Turning Machining Stainless Steel Parts

Professional Supplier OEM Service 304 316 Custom Precision CNC Turning Machining Stainless Steel Parts

CNC turning machining offers precise, efficient, and repeatable manufacturing of complex components with tight tolerances. It is widely used in various industries, including automotive, aerospace, electronics, medical, and more, to produce high-quality parts with excellent accuracy and consistency.

-

custom stainless steel cnc machined parts supplier

In embracing customization, we have honed our expertise in providing unmatched flexibility, enabling us to produce CNC parts that precisely accommodate the individual requirements of a vast range of projects and applications. This dedication to tailor-made solutions has established us as a trusted partner for companies seeking reliable and high-precision CNC parts designed to elevate their products and systems to new heights.

If you’re putting together heavy-duty industrial machines, building high-pressure fluid systems, or making medical equipment that needs to resist corrosion—let me tell you, stainless steel CNC parts are non-negotiable. These parts are machined so carefully, you’ll feel the difference in how they hold up: super reliable, long-lasting connections that don’t let you down. Wear, moisture, tough environments? They handle it all—no cutting corners on dependability here. And don’t sleep on their versatility: they fight off rust and chemical damage like a pro, stay strong even when under huge pressure, and fit right into those tight, complicated designs where regular parts just throw in the towel. When your project needs both durability and precision, these are the parts you want—no second thoughts.

Common Types of Stainless Steel CNC Parts

Stainless steel CNC parts are built for real-world tough jobs—some shine in high-stress mechanical work, others are total stars at dissipating heat, and a few fit like a glove into sensitive systems. They’re the most popular across pretty much every industry we work with:

Stainless Steel Shafts:Stainless steel shafts have this smooth, precisely ground surface—so smooth you can run your finger over them. Their diameter stays consistent too, even down to 0.01mm—super precise. And we can customize them with keyways, grooves, or threaded ends to transfer torque, whatever your project needs. They come in solid or hollow styles: solid ones are perfect for heavy-load jobs, like gearboxes—they won’t bend under pressure. Hollow shafts? They cut down on weight but don’t lose strength, which is great for rotating parts in pumps.

Stainless Steel Heat Sinks:Stainless steel heat sinks are CNC machined with fin structures that actually work—dense, thin fins mean more surface area to cool things down, and precise mounting holes that line up perfectly with your electronic parts. Here’s how we make them: start with a solid stainless steel block, then use CNC milling to carve out the fin patterns, and smooth the surface so heat transfers better. Unlike aluminum heat sinks, these can handle high temps and harsh chemicals without warping or rusting.

Stainless Steel CNC Part: Stainless Steel CNC Parts are meticulously crafted via computer numerical control (CNC) machining, featuring ultra-precise dimensions and seamless structural integrity—tight tolerances (often as low as ±0.005mm) ensure a perfect fit with assembly components, and robust material composition guarantees long-term reliability in heavy-duty use. Here’s how we create them: begin with high-grade stainless steel stock, program CNC lathes or mills to execute complex cutting paths, and finish with deburring and polishing to eliminate sharp edges and boost surface smoothness.

Application Scenarios of Stainless Steel CNC Parts

Picking the right stainless steel CNC part isn’t just about “fit”—it’s protecting your gear, extending its life, and keeping it running smooth in tough conditions. Below are the top real uses we see from customers:

1. Industrial Machinery & Heavy Equipment

Key Parts: Stainless Steel Gear Housings, Precision Stainless Steel Bearings, Thick-Walled Stainless Steel Brackets

Food plant conveyors: Precision bearings resist acids, water, and cleaners—no rust to jam parts (a rust shutdown is a production nightmare).

Construction hydraulic pumps: Gear housings handle high torque without warping—steady fluid flow, no leaks or downtime.

Factory compressors: Thick-walled brackets hold cooling parts tight and resist heat—motors stay cool 24/7.

2. Medical & Laboratory Equipment

Key Parts: Polished Stainless Steel Valve Bodies, Miniature Stainless Steel Fasteners, Stainless Steel Sensor Casings

Surgical robots: Polished valve bodies are easy to sterilize (works with autoclaves) and won’t contaminate sterile areas.

Blood analysis machines: Sensor casings protect parts and avoid metal leaching into samples (no messed-up results).

Dental drills: Mini fasteners stay tight through sterilization and keep rotation precise—no wobbly drills!

3. Marine & Coastal Applications

Key Parts: Stainless Steel Flange Plates, Marine-Grade Stainless Steel Couplings, Sealed Stainless Steel Junction Boxes

Boat propellers: Marine couplings fight saltwater corrosion—no rust, often lasting over a decade.

Yacht navigation: Sealed junction boxes protect GPS/radar wiring—handles humidity/splashes, no short circuits.

Offshore wind turbines: Flange plates hold sections together—resists winds/salt spray, stable power transfer.

How to Customize Exclusive Stainless Steel CNC Parts

At Yuhuang, customizing stainless steel CNC parts is way easier than you think—no guesswork, no confusing jargon, just parts made exactly for your project. We’ve done precision metal machining for years, so we know how to turn your blueprint into a perfect fit. Just share these key details, and we’ll handle the rest:

1.Material Grade: Not sure which to pick? 304 is the all-around choice (great for food, medical, light industrial use—good corrosion resistance and strength). 316 is marine-grade (fights saltwater/chemicals). 416 machines easily and stays strong (perfect for shafts needing tight tolerances). Tell us your environment (saltwater? High heat?) and strength needs—our engineers will point you to the right one, no guesswork.

2.Type & Function: Need a stainless steel shaft? We customize length (10mm to 2000mm), diameter (M5 to M50), and features (keyways, threaded ends, hollow cores). For heat sinks? Adjust fin density (more fins = better cooling), height (for tight spaces), and mounting holes. Even weird requests—curved heat sinks, stepped shafts—we’ve done it.

3.Dimensions: Be specific! For shafts, share diameter tolerance (we hit ±0.02mm for precision), length, and feature sizes (like a 5mm keyway). For heat sinks, tell us fin thickness (down to 0.5mm), spacing (for airflow), and overall size. We match your blueprint exactly—no rework, we hate that too.

4.Surface Treatment: Want it polished (mirror for visible parts, matte for low-key)? Passivated (boosts corrosion resistance for marine use)? Sandblasted (non-slip for easy installation)? We also do anti-fingerprint or thermal conductive coatings—just say what you need.

Share these details, and first we’ll confirm it’s doable (spoiler: it almost always is). Need advice? Our engineers help for free. Then we’ll manufacture and deliver on time—we know deadlines matter.

FAQ

Q: How to pick the right stainless steel CNC part?

A: Food/medical: 304 (easy to sterilize, anti-rust). Marine: 316 (saltwater-proof). High-torque machines: 416 shafts. Match part type (e.g., shafts for rotation). Stuck? Share project details for help.

Q: What if a shaft bends or heat sink fails to cool?

A: Stop use. Bent shaft: Maybe wrong grade (e.g., 304 for heavy loads) – upgrade to 416. Poor cooling: Add fin density/thermal coating. Replace and adjust specs if needed.

Q: Do stainless steel CNC parts need maintenance?

A: Yes, simple: Wipe dirt/moisture with soft cloth; mild soap for polished parts. Rinse marine parts after saltwater use. Yearly check for scratches – fix small issues with passivation.

Q: Can stainless steel heat sinks handle 500°C electronics?

A: Yes. 304 (up to 800°C) or 316 work; optimize fins. Avoid 430 (warps). Ask for grade advice by temperature.

Q: Is 316 better than 304 for shafts?

A: Depends. Yes for saltwater/chemicals/harsh areas. No for general use (food/medical/dry) – 304 is cheaper. Ask engineers via environment details.

Q: How long for custom stainless steel CNC parts?

A: Simple (e.g., basic shafts): 3-5 workdays. Complex (e.g., custom heat sinks): 7-10 days. Clear timeline; urgent orders can be prioritized.

Bolts

Bolts Nuts

Nuts Wrenches

Wrenches Spring

Spring