Common Types of stamping parts

Stamping parts are manufactured for the demands of industrial production - some can precisely fit complex assembly Spaces, some can stably bear the operating loads of equipment, and others merely meet simple connection requirements. These three are the ones you come into contact with most frequently:

1.Stainless Steel Stamped Parts

Ideal for parts that need to resist rust or stay clean. You’ll find them in:

•Medical tools and devices (they meet strict hygiene rules)

•Food processing machines (stand up to water and cleaning chemicals)

•Car exhaust systems (handle high heat without corroding)

These parts last for years, even in harsh conditions.

2.Aluminum Stamped Parts

Perfect when you need something light but strong—no extra weight weighing your product down. Common uses include:

•Aerospace parts (keep planes and drones light for better fuel efficiency)

•Car body panels (strong enough for daily use, light enough to boost mileage)

•Electronic cases (like laptop or tablet frames—sleek and durable)

Aluminum also resists rust, so it works just as well indoors as it does outside.

3.Copper Alloy Stamped Parts

The go-to choice for parts that need to conduct electricity or heat well. They’re key in:

•Electrical connectors (like USB ports or battery contacts—no power loss)

•Circuit breakers and transformers (keep power systems running smoothly)

•Heat sinks (cool down CPUs or LED lights to prevent overheating)

You can count on these parts for consistent performance in electronics and power equipment.

The right stamped part can make or break your product. We supply parts to four major sectors:

1. Automotive Manufacturing

•Parts We Make: Engine brackets, suspension mounts, sensor housings, electrical contacts.

•Why It Matters: Our parts meet the strict standards cars demand—strong enough for bumpy roads, precise enough for safety systems, and affordable for large production runs. They help make vehicles safer and more efficient.

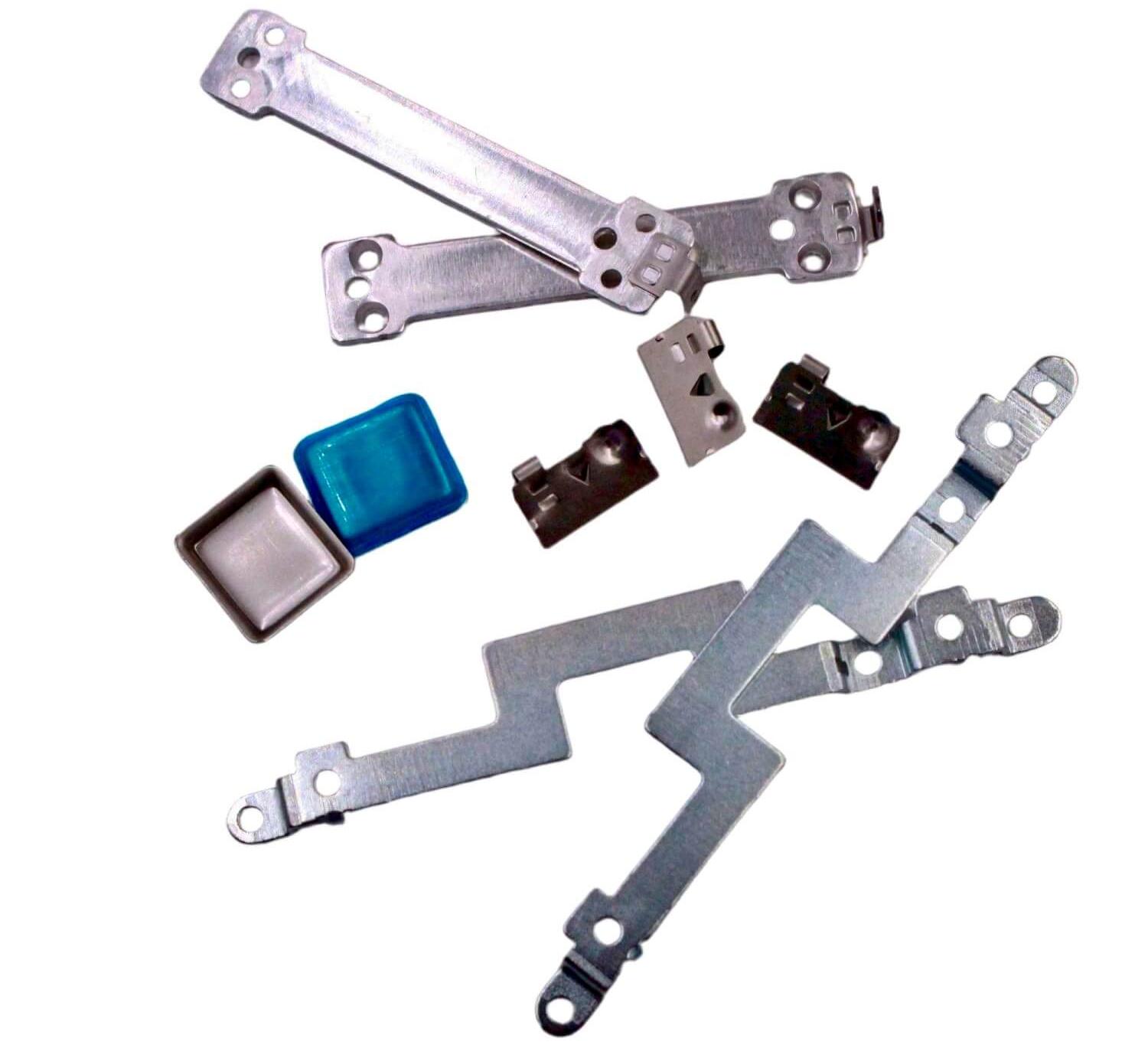

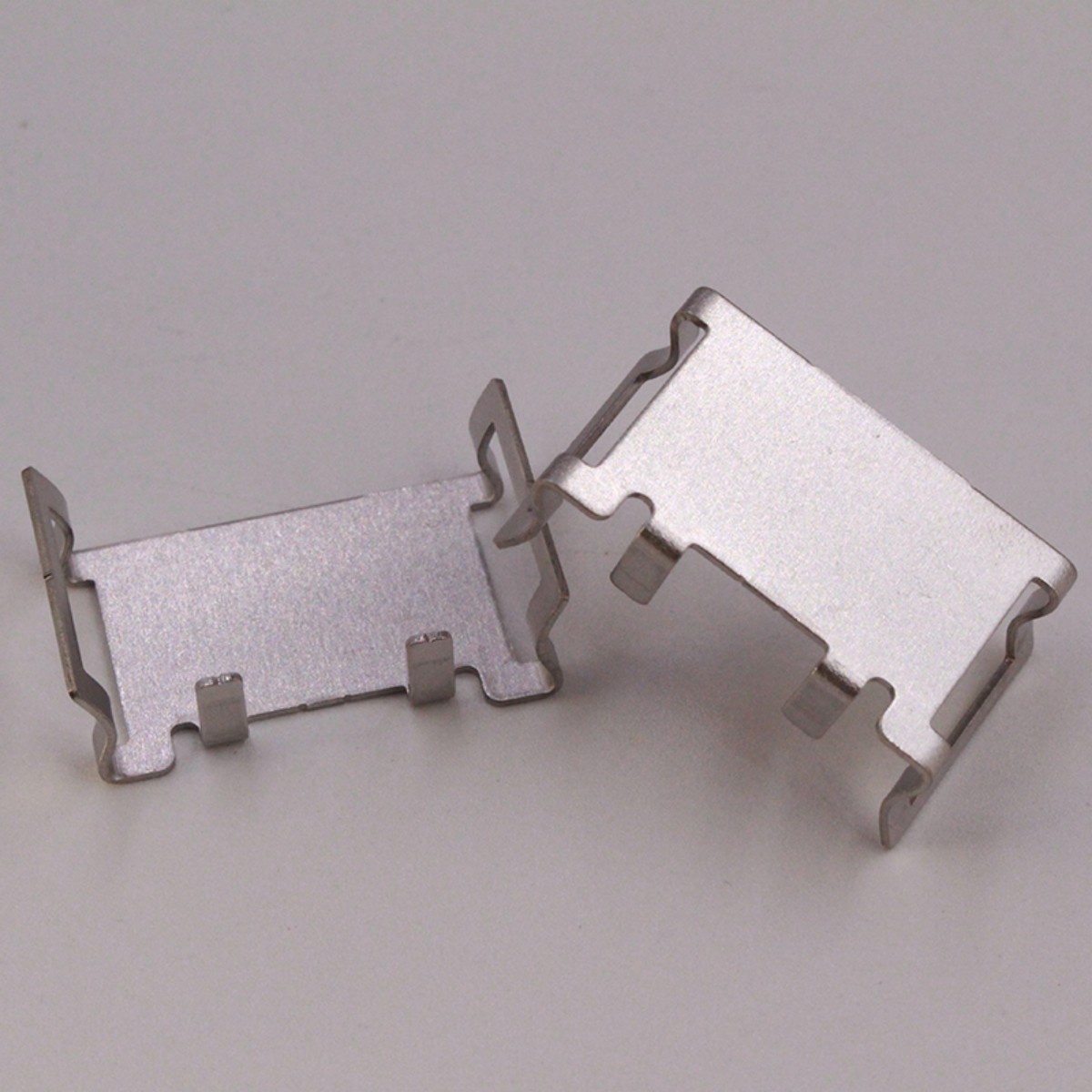

2. Electronics & Telecommunications

•Parts We Make: Shielding cans (block interference), connector leads, battery contacts, tiny parts for wearables.

•Why It Matters: Electronics need parts that fit perfectly—our stamping hits tolerances as tight as ±0.02mm. That means no loose connections or broken parts in phones, routers, or medical monitors.

3. Industrial Machinery

•Parts We Make: Motor laminations, gearbox components, structural supports, hydraulic brackets.

•Why It Matters: Industrial gear works hard—our parts handle vibration, heavy loads, and constant use. They keep conveyor belts, construction machines, and robots running day in and day out.

How to Customize Exclusive Stamping Partner

At Yuhuang, we don’t just make parts—we help you build the right part for your project. Here’s how we work:

1.Pick the Right Metal: Our team helps you choose between stainless steel, aluminum, copper, or specialty alloys. We’ll factor in strength, rust resistance, cost, and any other needs your project has.

2.Tweak Your Design: Share your drawings or ideas—we’ll check if they’re easy to stamp (that’s called DFM analysis). We’ll suggest small changes to make the part stronger, cheaper to produce, or faster to make.

3.Make the Parts Precisely: We use stamping presses (from 10-ton to 300-ton) and custom tools to hit your exact dimensions. Whether you need 10 prototypes or 100,000 parts, we’ll scale to your order.

4.Finish the Job: We can add extras to get parts ready for use—like plating (to prevent rust), heat treatment (to make parts harder), or assembly (putting parts together into a bigger component).

5.Check for Quality: We never skip quality checks. We use tools like CMM machines (to measure tiny details) and optical comparators (to check shapes) to make sure every part is right. We follow ISO 9001 and IATF 16949 standards—so you know you’re getting consistent quality.

FAQ

Q: Why choose metal stamping over machining?

A: Stamping is faster and cheaper when you need lots of parts. It wastes less metal, and you can make complex shapes that would cost a fortune with machining. Plus, every part comes out the same—no inconsistencies.

Q: What file formats do you need for a quote?

A: PDF, DWG (2D drawings) or STEP, IGES (3D models) work best. Just include details like metal type, thickness, dimensions, surface finish, and how many parts you need.

Q: Can you make parts with super tight tolerances (like ±0.01mm)?

A: Yes. With our precision presses and tooling, we can hit ±0.01mm for small parts. We’ll talk through your needs first to make sure it’s doable.

Q: How long does it take to get custom parts?

A: Prototypes (using existing tools) take 1–2 weeks. For custom tools and big orders, it’s 4–8 weeks. We’ll give you a clear timeline once we confirm your order.

Q: Do you make samples before full production?

A: Definitely. We’ll make a few prototypes first so you can check if they fit and work. It’s a great way to fix issues early—saves time and money later.

Bolts

Bolts Nuts

Nuts Washers

Washers Spring

Spring