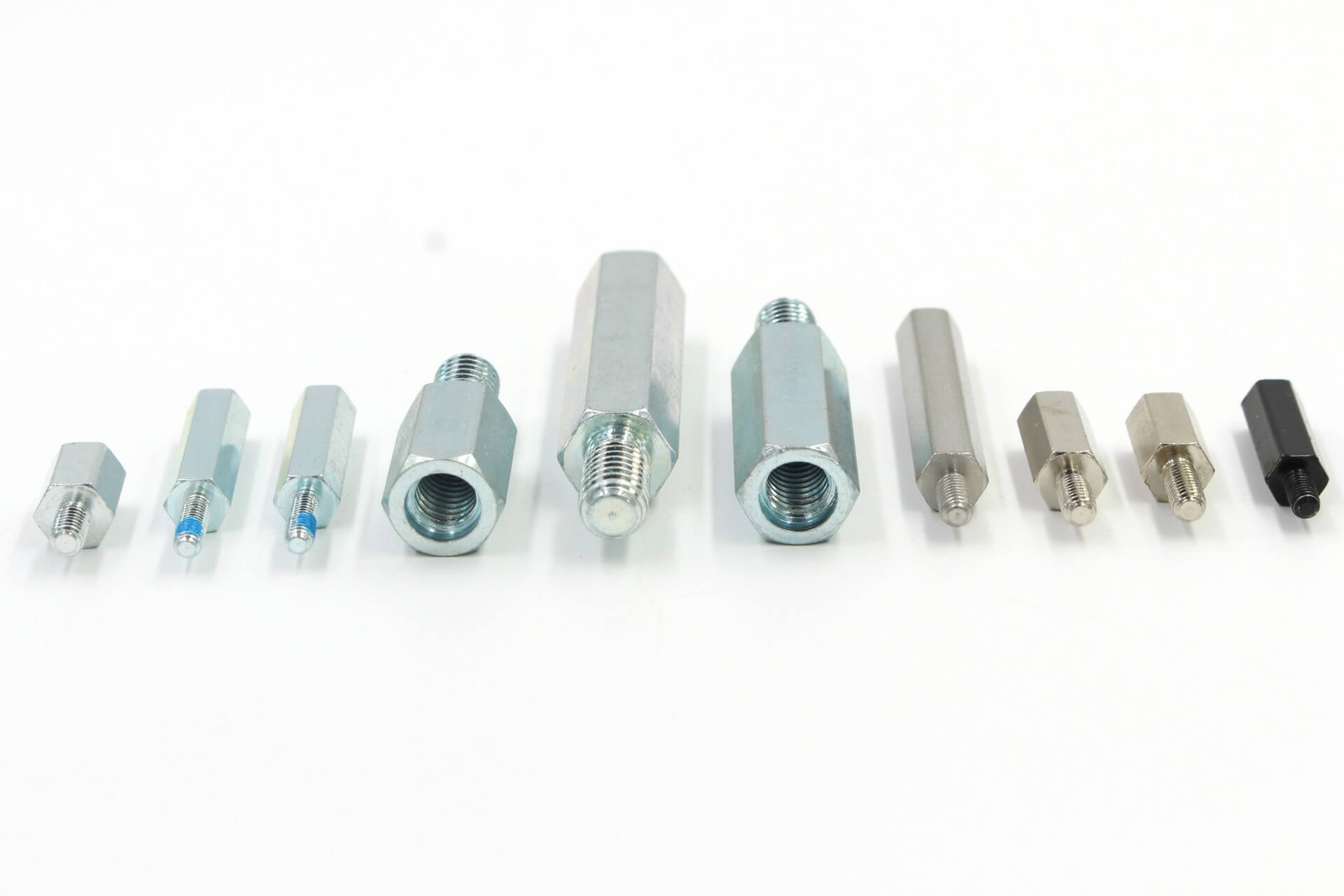

Common Types of Standoffs

Standoffs are built for real - world fastening needs—some prioritize corrosion resistance for outdoor use, others focus on strength for heavy loads, and some excel in precision for electronics. These three are the ones you’ll reach for most in mechanical and electronic work:

Stainless Steel Standoffs:The all - around performer with excellent rust resistance and moderate strength. Made from 304 or 316 stainless steel, it stands up to damp environments and frequent cleaning without corroding. Its best feature? It balances durability and cost - effectiveness, so it’s great for applications where hygiene and long - term use matter.

Carbon Steel Standoffs:The heavy - duty choice for high - load scenarios. Crafted from high - carbon steel, it boasts superior tensile strength and impact resistance—able to handle intense pressure from industrial machinery or automotive chassis. Its key advantage? It’s easy to customize and offers strong gripping force once riveted.

Zinc - Plated Standoffs:The cost - effective solution for general - purpose fastening. Made from low - carbon steel with a zinc coating, it provides basic corrosion resistance at a lower price point than stainless steel. The zinc layer acts as a barrier against moisture, making it suitable for indoor or mild outdoor use. Its biggest benefit? It’s compatible with most metals and plastics, and the smooth plating ensures easy installation.

Application Scenarios of Standoffs

Picking the right standoff isn’t just about fastening parts—it also protects components, ensures assembly precision, and extends the lifespan of your equipment. Here’s where you’ll use them most:

1. Electronics and Electrical Equipment

Go - to standoffs: Stainless Steel Standoffs, Miniature Zinc - Plated Standoffs

What you’ll use them for: Running circuit board (PCB) assembly? Stainless steel standoffs space multiple PCBs in routers or servers, preventing short circuits from direct contact while allowing airflow for heat dissipation. Securing smartphone or laptop casings? Miniature zinc - plated standoffs secure internal components (like batteries or screens) without adding bulk—keeping devices slim and lightweight. Operating power supply units? Standoffs fasten transformers and capacitors to the housing, reducing vibration that could damage sensitive parts and ensuring stable power output.

2. Automotive and Transportation

Go - to standoffs: Carbon Steel Standoffs, Zinc - Plated Standoffs

What you’ll use them for: Adjusting automotive interiors? Carbon steel standoffs reinforce dashboard panels and door trims, withstanding daily wear (like opening/closing doors) without bending. Steering or securing components in light vehicles (like golf carts or electric scooters)? Zinc - plated standoffs secure battery compartments—resisting mild moisture from rain or spills to keep electrical connections safe. Fastening parts in heavy trucks? High - strength carbon steel standoffs fasten chassis components, handling road shocks and heavy loads without loosening.

3. Medical and Precision Instruments

Go - to standoffs: Stainless Steel Standoffs, High - Precision Standoffs

What you’ll use them for: Operating medical devices (like MRI machines or blood analyzers)? Stainless steel standoffs meet strict hygiene standards—they’re easy to sterilize with chemicals and won’t contaminate samples. Running lab equipment (like centrifuges or microscopes)? High - precision standoffs ensure components stay aligned, preventing vibration that could skew test results. Assembling prosthetic devices (like robotic arms)? Miniature stainless steel standoffs secure small motors and sensors, providing stable support while keeping the device lightweight for user comfort.

How to Customize Exclusive Standoffs

At Yuhuang, customizing standoffs is easy—no guessing, just parts that fit your system perfectly. All you have to do is tell us a few key things:

Material: What’s the job?

• Stainless steel is great for medical, food, or marine use (like medical devices or marine electronics) because it’s rust - resistant and meets hygiene standards.

• Carbon steel works for high - load, heavy - duty spots (like industrial machinery or automotive chassis) since it’s strong and easy to customize.

• Zinc - plated steel is the top pick for cost - sensitive, indoor applications (like consumer electronics or office furniture)—it provides basic rust protection and is budget - friendly.

1. Type: What kind do you need?

Threaded standoffs can be tweaked with different thread sizes (like M3 or M5) to match the screws you use. Spacer standoffs come in solid or hollow designs, depending on whether you need to pass wires through. We also make combo types (like stainless steel body + zinc - plated threads) for tricky fastening jobs.

2. Dimensions: Specific sizes?

For standoffs, tell us the length (to fit the thickness of your components), outer diameter (to fit into mounting holes), and inner diameter (for threaded or hollow types). For threaded standoffs, share the thread pitch (coarse or fine) and depth (how far the screw needs to engage). Don’t forget the mounting style (flat base, flanged end, or countersunk) for easy installation.

3. Surface Treatment: How to boost performance?

• Passivation treatment makes stainless steel standoffs more rust - resistant—good for medical or food industry gear.

• Chrome plating adds a shiny finish and scratch resistance, great for visible components in automotive interiors.

• Powder coating provides a thick, durable layer that withstands impact and chemicals, suitable for industrial standoffs.

• Zinc plating (for carbon steel) is cheap and works for mild rust spots (like indoor electrical boxes).

4. Special Needs: Anything extra?

Need a standoff that resists high heat (like engine parts)? We can use heat - resistant materials (like 310 stainless steel) that work even up to 600°C. Want to add insulation to prevent electrical conduction? We’ll add a plastic sleeve around metal standoffs. Need custom markings (like part numbers)? We’ll do laser etching during manufacturing.

Share these details, and we’ll first check if it’s doable. If you need advice on picking materials or adjusting sizes, we’ll help—then send you standoffs that fit like a glove.

FAQ

Q: How to pick the right standoff length?

A: Measure how thick all the parts you need to fasten are (total). If you need a small gap—like 1-2mm for airflow or adjusting during assembly—add that. The standoff length should match this total. No gap? Just use the exact total thickness of the parts.

Q: Can I use zinc-plated standoffs outside?

A: They only work short-term in mild outdoor spots (like covered, dry electrical boxes) since they just have basic rust protection. Skip harsh places—rain, saltwater, chemicals. Use 304/316 stainless steel or hot-dip galvanized carbon steel instead.

Q: What if my threaded standoff doesn’t fit my screw?

A: First check the thread details (size, pitch) of both. We can get you screws that match your standoffs, or make custom standoffs to fit your screws—just tell us your screw’s info (size, pitch, metric/imperial).

Q: How to keep standoffs in good shape?

A: - Stainless steel: Wipe with a clean, dry cloth—don’t use scratchy cleaners.

Plated carbon steel: Brush off small rust with a soft brush, then put on anti-rust oil.

Never tighten screws too much—you’ll damage threads or bend the standoff.

Q: Is there a minimum number I have to order for custom standoffs?

A: No strict minimum. We do 10 (for prototypes) up to 10,000 (mass production). Bigger orders have better per-unit prices, but small ones still have the same precision and quality. Our team can help suggest how many to get.

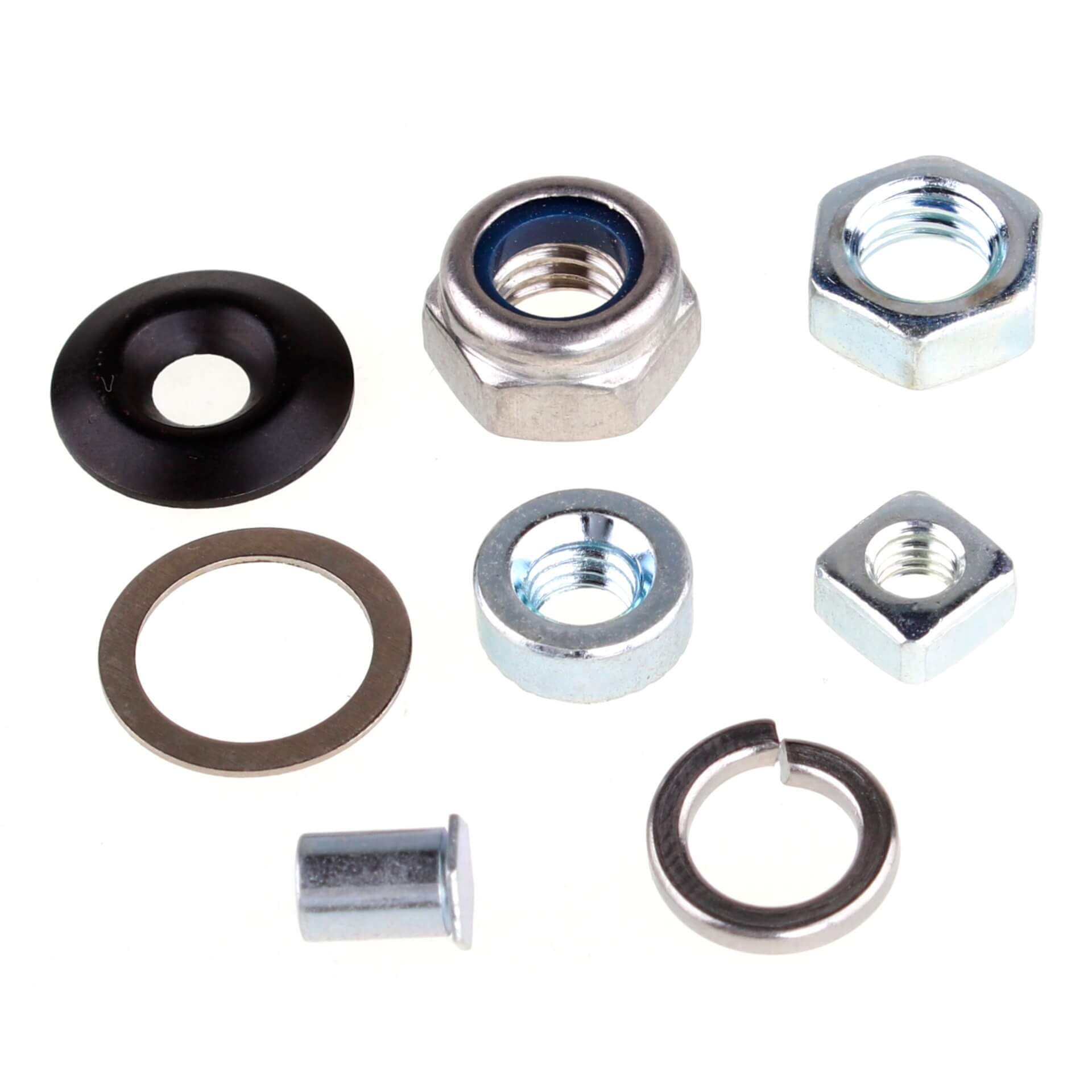

Bolts

Bolts Nuts

Nuts Washers

Washers Screw

Screw