Common Types of Gears

Gears are built for real-world needs—some handle high-speed power transfer like a pro, others focus on precision, and some fit into tight installation spots. These three are the ones you’ll reach for most in mechanical work:

Spur Gears:The most basic but widely used type, with straight teeth that run parallel to the gear’s axis. Its best feature? Simple to make and won’t break the bank, so it’s great for jobs where speed and torque needs are moderate. You’ll spot them in everyday stuff—like blenders, washing machines, or small industrial gear like conveyor drives and basic gearboxes. They get power from point A to point B without any fancy setup.

Helical Gears:Stand out with angled (helical-shaped) teeth that mesh slowly with matching gears. Unlike spur gears, they run way quieter and with less vibration—thanks to the smooth, constant contact between teeth. They’re made for high-speed, high-torque jobs: think car transmissions, industrial pumps, or heavy machinery like manufacturing robots. They can handle more load than spur gears too, so they’re a top pick for systems that need to run reliably long-term.

Gear Shafts:A 2-in-1 part that combines a gear (could be spur, helical, or another type) with a shaft—no need to mount a separate gear. Its big advantage? Super sturdy structure. Since the gear and shaft are one piece, there’s less room for assembly mistakes, and power transfers more efficiently. You’ll find them in precision gear like machine tool spindles, car differential systems, or aerospace parts—places where space is tight and you can’t afford energy loss.

Application Scenarios of Worm Gears

Picking the right worm gear isn’t just about matching speed and torque—it also keeps your whole mechanical system safe, efficient, and long-lasting. Here’s where you’ll use them most:

1. Industrial Machinery and Equipment

Go-to worm gears: High-torque Worm Gear Reducers, Compact Worm Gear Boxes

What you’ll use them for: Running factory conveyors? A worm gear reducer dials down the motor’s high speed to a pace that’s right for the conveyor, while pushing out enough torque to move heavy loads. Lifting gear like overhead cranes or hoists? The self-locking feature on worm gears keeps loads from dropping if power cuts out—total workplace saver. Mixing machines in chemical or food plants? Worm gears keep mixing blades turning steady, no sudden speed jumps that mess up product quality.

2. Automotive and Transportation

Go-to worm gears: Low-noise Worm Gears, Corrosion-resistant Worm Gears

What you’ll use them for: Adjusting car seats? Small worm gears in seat mechanisms let you move seats precisely and quietly—no loud clicks or jolts. Steering systems in light vehicles like golf carts or small trucks? Worm gears cut down on backlash (that loose feeling in steering) to make control sharper. Trailer brakes? Corrosion-resistant worm gears hold up in outdoor and damp conditions, so braking force stays reliable even when it’s rainy or dusty.

3. Medical and Precision Instruments

Go-to worm gears: Miniature Worm Gears, High-precision Worm Gears

What you’ll use them for: Medical imaging gear like MRI or CT scanners? Miniature worm gears move scanning parts exactly where they need to go—no vibration that blurs images. Lab centrifuges? High-precision worm gears keep rotation speed steady, which is key for separating samples right. Prosthetic devices like robotic arms? Small, light worm gears give just enough torque for natural, controlled movement, making life easier for users.

How to Customize Exclusive Worm Gears

At Yuhuang, customizing worm gears is easy—no guessing, just parts that fit your system perfectly. All you have to do is tell us a few key things:

Material: What’s the job? Alloy steel is great for high-torque, heavy-duty work (like industrial machinery) because it’s strong and resists wear. Brass works for low-load, rust-prone spots (like marine gear) since it doesn’t corrode and is easy to machine. Stainless steel is the top pick for medical or food industry gear—it meets hygiene rules and stands up to frequent chemical cleaning.

1.Type: What kind do you need? Worm gear reducers can be tweaked with different reduction ratios (like 10:1 or 50:1) to match how fast or strong you need the output. Worm gear boxes come in compact or large sizes, depending on how much space you have. We also make combo types (like worm gear + helical gear) for tricky power transfer jobs.

2.Dimensions: Specific sizes? For worm gears, tell us the number of starts (1-start for more speed reduction, multi-start for better efficiency), pitch diameter (to fit with other parts), and face width (affects how much load it can handle). For worm gear boxes, share the overall length, width, and height to make sure it fits your equipment. Don’t forget shaft diameter and how you’ll mount it (flange or foot-mounted) for easy installation.

3.Surface Treatment: How to boost performance? Hard chrome plating makes it more wear-resistant—good for high-friction jobs. Black oxide coating adds basic rust protection and looks sleek, great for indoor machinery. Zinc plating is cheap and works for mild rust spots (like car undercarriages). For medical gear, we do passivation treatment to meet strict hygiene and anti-rust standards.

4.Special Needs: Anything extra? Need a worm gear that locks itself for safety-critical work? We can adjust the lead angle to make that happen. Want to add sensors for speed checks? We’ll leave holes for sensors during manufacturing. Need it to handle high heat (like engine parts)? We’ll use heat-resistant materials and coatings that work even up to 300°C.

Share these details, and we’ll first check if it’s doable. If you need advice on picking materials or adjusting sizes, we’ll help—then send you worm gears that fit like a glove.

FAQ

Q: How do I choose the right worm gear reduction ratio?

A: Easy—just use your motor’s input speed and the output speed you actually need. Like, if your motor runs at 1500 RPM and you need 30 RPM out, a 50:1 ratio works perfectly. If you’re lifting heavy stuff (and need lots of torque), go for a higher ratio—80:1 or even more. But for things like conveyors, where efficiency matters most, stick to a lower ratio (10:1 to 30:1) or grab a multi-start worm gear.

Q: What if the worm gear’s making too much noise?

A: First, check the lube—if there’s not enough, or you used the wrong kind (worm gears need high-viscosity oil, remember?), that’s probably why it’s loud. If the oil’s good, the worm and worm wheel might not be lined up right. Tweak their mounting until they mesh properly. Still noisy? Then the teeth are probably worn or damaged—swap the whole set fast, otherwise you might break other parts too.

Q: Is a self-locking worm gear enough for all safety jobs?

A: Not always. Self-locking depends on the lead angle—smaller angles lock better—but tough conditions (like big shocks or cold weather that thickens the oil) can break that lock. For super safety-critical stuff, like elevator lifts, pair the self-locking worm gear with an extra brake. Hit up our team to make sure it’s safe enough for what you’re doing.

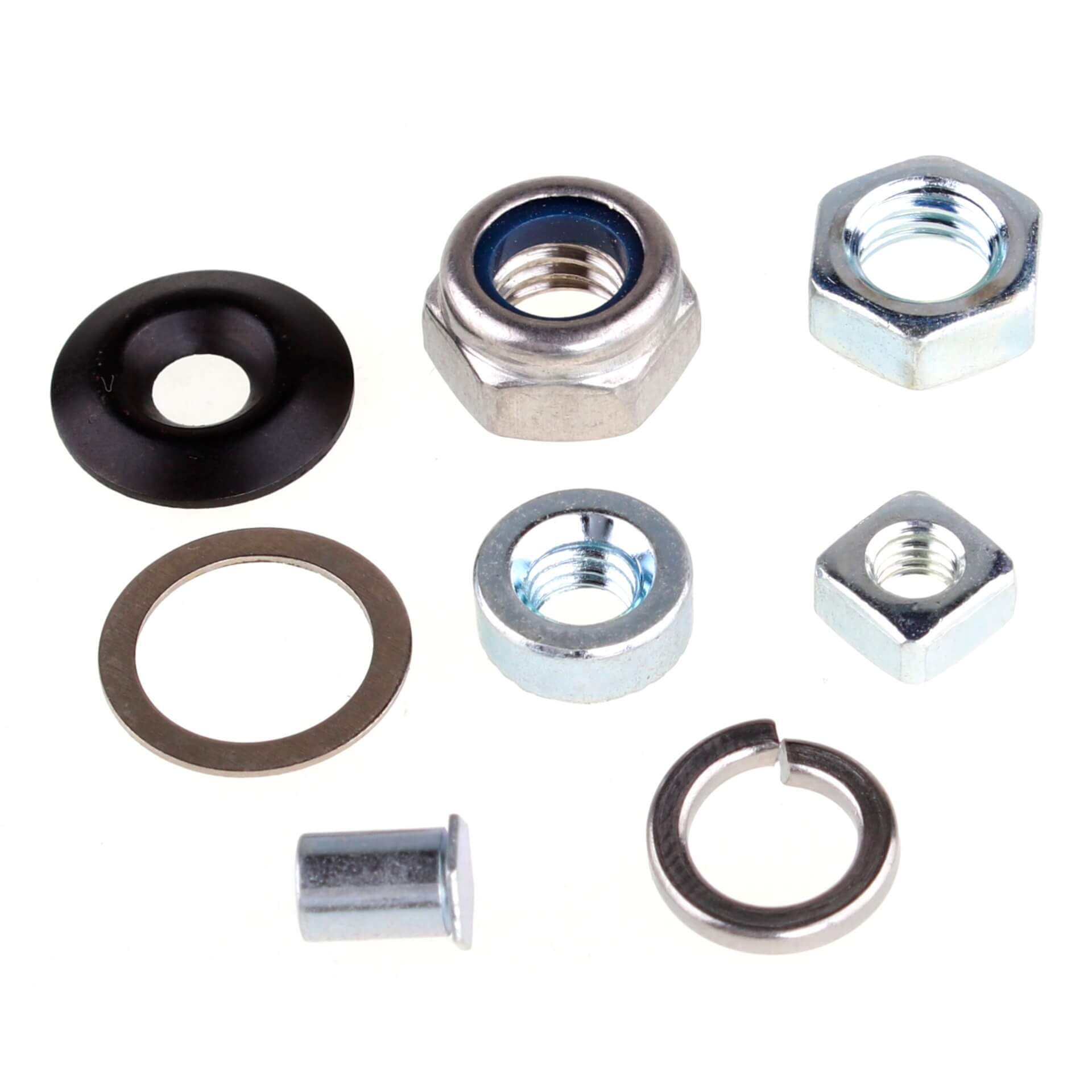

Bolts

Bolts Nuts

Nuts Washers

Washers Screw

Screw